Why Do Pumps Fail? Current

Pumps are used to transfer liquid. So why do pumps fail? Why do well submersible pump failures occur? Reasons for water pump failure with you.

Pumps are used in many areas from garden irrigation to oil transfer. Pumps with mechanical structures are designed to ensure healthy operation for a long time. However, when the appropriate conditions are not met, it suddenly breaks down. The engine burns out, the packing gives out.

Checking the fittings in centrifugal pumps reveals a large number of causes of failure. For this reason, constantly check the work done when making connections. A significant proportion of water pump failuresare caused by the end of life of the parts.

Correctly selecting the areas of use is another important factor for your pump not to malfunction. At the same time, it is useful to check frequently to prevent malfunction. In hydraulic pump types, it is important to ensure hydraulic control because it may cause hydraulic failure.

If you have been around irrigation and pumping stations, you have probably noticed that not everything goes as planned. Below, we have written a few tips to prevent why pumps fail.

Why Pumps Fail Lack of Suction Water

Lack of water can be caused by a number of different factors. A water-starved irrigation pump significantly shortens the life of the pump. There may be insufficient water in the suction part or it may become clogged.

For example, plastic bags can wrap around the impellers in a suction screen. Frogs (or fish or…), sediments, weeds and debris can also clog the suction strainers. You can use a strainer to prevent this problem.

Other factors can also cause low water supply:

- Sometimes the water supplied from the pond, stream, well, or reservoir is less than the amount absorbed by the pump.

- The water level in the wells may drop during pumping and cause the pump to run without water.

- Finally, booster pumps can run out of water if there is a problem with the pipeline.

Irregular Electric Current

Motors need electric current to run the pumps. According to the power of the motor, single-phase or three-phase electricity is used. But in city networks, the voltage may fluctuate due to sudden power outages. This sudden voltage change causes irrigation pump failures.

- If the voltage is low, the motor will burn from overheating because it will work with difficulty.

- When high voltage comes in, it damages the electrical parts inside and explodes the winding.

Especially submersible pump failure is caused by this situation. You can use a protection and control panel to prevent pump failures due to electric current.

Why Pumps Fail Dirty Water

Water can be contaminated in various ways. Large particles can clog suction strainers. Small particles such as silt and sand are very difficult and costly to filter. They are also very abrasive.

These small particles can significantly shorten the life of the pump and valves. Chemicals in the water can damage pump materials and seals. The pump dealer should understand the water quality very well before specifying pump materials.

The pump should be selected according to the pollution of the water. Otherwise, it will be possible to encounter pump failure in a short time.

Why Pumps Fail Poor System Design

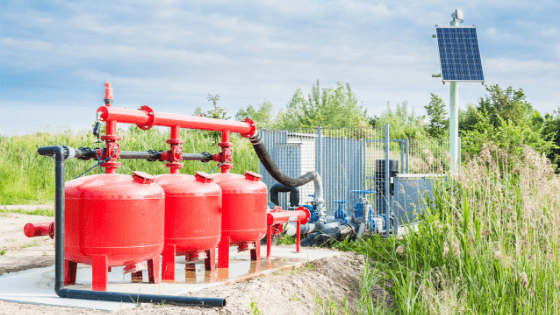

Some pumping systems are subject to problems from the day they are commissioned due to poor design. The market is full of pump designs and configurations that serve specific purposes.

A pump can work perfectly in one application and fail abruptly in another. Controls and auxiliary equipment are crucial to the success of any pumping system.

Auxiliary equipment should be selected according to the intended use of the pumps, and they should be located in suitable places that do not receive sunlight and rainwater.

Why Does a Submersible Pump Burn?

The importance of motor protection in submersible pumps is different from that of dry type motors due to the operating environment. There are basically 3 different faults in submersible motors. Electrical, mechanical, electrical faults caused by mechanical faults.

One of the most common faults is the burning of 80% strator windings. This is caused by phase loss, voltage fluctuation, unbalance and overload. Primary and secondary fa

Phase Loss

Depending on the motor side of the grid, primary and secondary phase loss occurs.

Voltage Fluctuation

The effects of voltage fluctuations in submersible motors are different from those in box type water motors. Increasing and decreasing voltage in submersible motors causes the current to increase. The voltage tolerance in motors is +10, -10 and there are very slight fluctuations in the motor current between these values. Low voltage is more common than high voltage.

Voltage increases by 10%: Pump speed increases, flow rate and pressure increase in parallel and this increases the motor current.

If the voltage increases by more than 10%: the starting torque and current of the motor increases compared to the other. It causes fatigue of the column pipes and mechanical installations and damage to the panel elements.

10% decrease in voltage: Pump speed decreases, flow rate and pressure decrease. motor current increases.

Voltage drop of more than 10%: Motor current drops significantly and overload protectors are activated.

Voltage Instability

Voltage unbalance is the most common cause of failure in submersible motors. Voltage unbalance is defined as the difference between the voltages in all three phases of the motor. Even if the voltage values in all three phases are within tolerances, there may be an imbalance problem.

Possible Causes of Voltage Instability

- Unbalanced distribution of single-phase loads,

- Poor quality network,

- Power factor not rising properly,

- Phase earth short circuits,

- Existing open circuits in the distribution system,

may cause voltage imbalance. Regardless of the type of motor against voltage imbalance, when connecting the motor to the mains, all three phases are connected by shifting in sequence. Since the three phases are shifted, the direction of rotation does not change. Whichever connection type creates the lowest unbalance situation is left connected in that way.

Overload

Submersible moto panels operate between -10°C and +50°C. Different temperature values cause the opening and closing values of thermal relays to change. This type of relays delays the motor deactivation and the motor burns out.

In short, irrigation pump failures are caused by lack of appropriate equipment and use of the pump. When the conditions suitable for the way the pump works are provided, there will be no problems.

All companies producing pumps provide 24 months warranty for possible failures. But this warranty is guaranteed against fabrication defects. Damages due to user error are not covered by the warranty. Especially engine combustion is not covered by the warranty.

Pump repair price varies between 3/1 price and 3/2 price of zero value. In determining these prices, expenses such as the price of parts to be replaced and labor are calculated.

It is also possible to get support and advice for pump motor failures by contacting our pump technicians at 444 5 622.

You can subscribe to our newsletter to be instantly notified of the next article and share it on your social media accounts if you find it useful. You can comment with your questions and comments. Click here for detailed information about submersible pumps.