What is Inline Pump? Wet-Dry Rotor Inline Pumps

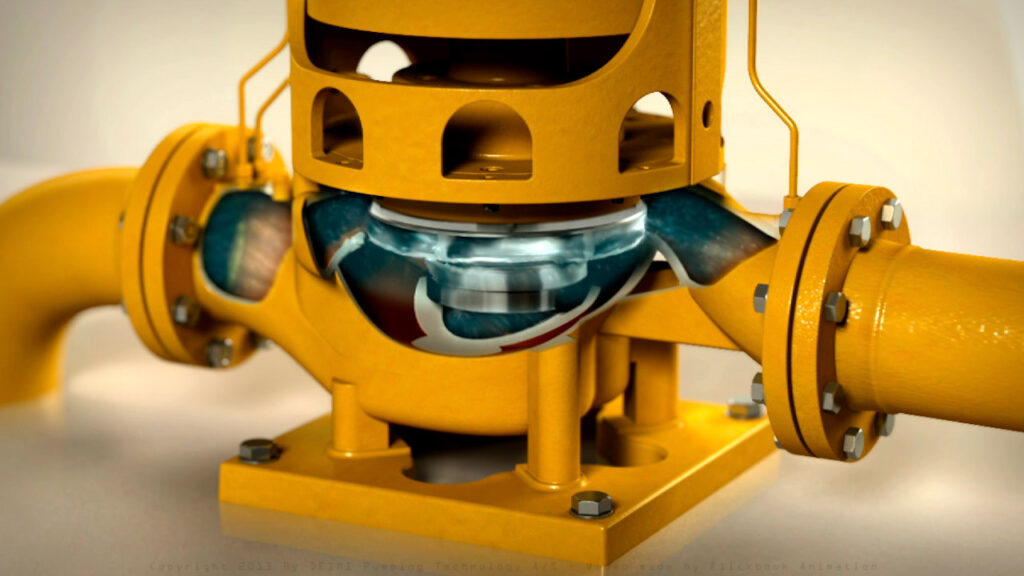

An inline pump is a type of pump used to transfer a liquid from one point to another in a pipeline. They are usually small, compact and lightweight, making them ideal for use in small spaces.

Table of Contents

It can be used to pump various liquids such as water, oil and chemicals.

It consists of an impeller and a motor. The impeller rotates on a shaft and moves the liquid through the pipeline. The motor provides the rotation in the impeller.

It is usually powered by electric motors, but some models can also be powered by hydraulic or pneumatic motors. They are used in various industries.

Inline Pump Usage Areas

Among the most common uses:

- Water heating and cooling systems

- Air conditioning systems

- Heating and cooling systems

- Chemical processing plants

- Food and pharmaceutical industry

- Automobile industry

- Aviation industry

It has several advantages.

Inline Pump Advantages

The most important advantages are:

- Small, compact and lightweight

- Can pump a wide range of liquids

- High efficiency

- Long service life

- Easy to maintain

It also has some disadvantages.

Disadvantages of Inline Pump

The most important disadvantages are:

- Not suitable for pumping high pressure liquids

- Not suitable for pumping high temperature liquids

- Not suitable for pumping heavily contaminated liquids

They are versatile and efficient pumps used for pumping a variety of liquids. They are small, compact and lightweight, making them ideal for use in small spaces. They are used in various industries and have many advantages.

Inline Circulation Pump Selection

The choice of inline circulation pump depends on the application for which the pump will be used. It can be used to pump a variety of liquids, but each liquid requires a different type of pump. Here are some factors to consider when choosing a pump:

- Type of liquid to be pumped: It can be used to pump water, oil, chemicals and other liquids. However, each liquid requires a different type of pump. For example, centrifugal pumps are used to pump high viscosity liquids, while diaphragm pumps are used to pump low viscosity liquids.

- Temperature of the liquid to be pumped: It should also be selected according to the temperature of the liquid. For example, for pumping high temperature liquids, high temperature resistant pumps should be used.

- Pressure of the liquid to be pumped: It should also be selected according to the pressure of the liquid. For example, to pump high-pressure liquids, high-pressure pumps should be used.

- The amount of liquid to be pumped: It should also be selected according to the amount of liquid to be pumped. For example, for pumping large quantities of liquid, high capacity pumps should be used.

When choosing an inline pump, the above factors should be taken into consideration. A pump suitable for the application where the pump will be used should be selected.

Some other factors to consider in its selection are:

- Size of the pump: Available in various sizes. The size of the pump should be selected according to the area where it will be used.

- Weight of the pump: Available in various weights. The pump should be easy to weigh, transport and install.

- Price of the pump: Available in various prices. The price of the pump varies according to the features and quality of the pump.

The choice of line type pump is an important decision. A pump suitable for the application where the pump will be used should be selected. The size, weight and price of the pump should also be considered.

Click here for inline pump prices. Click here for detailed information about circulation pumps. Click here for more information about flanges.