What is Cavitation in Pumps? What Causes It?

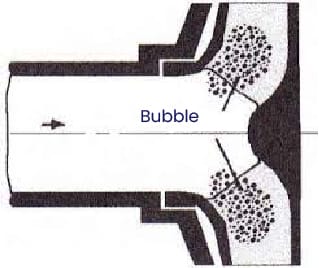

What is cavitation? It occurs in the form of the formation and sudden bursting of vapor-filled bubbles in systems. It usually occurs as a result of the vapor pressure of the pumped fluid being higher than the pump pressure.

Table of Contents

Cavitation damage is a threat to our pump. the way to prevent this is to have a minimum pressure at the suction nozzle, defined as positive suction head (NPSH), so that the liquid does not boil or vaporize.

This minimum pressure prevents cavitation. The pressure at the suction nozzle must be higher than the fluid vapor pressure.

If there is cavitation damage in the pump, the control valve located on the pressure side is throttled. This reduces the flow rate and the required NPSH value.

The important point is that the flow rate must be high enough to cool the pump. As a result of the cavitation problem, small gas bubbles form in the liquid. Over time, the capacity of the pump decreases and its life is shortened.

It also causes noisy operation of the pump. So what is cavitation? It occurs as a result of the rapid movement of the substance in the fluid and can be characterized as a phase change.

ENPYT – Plant Net Positive Suction Load

By evaluating the conditions such as geographical height and liquid temperature in the facility where the pump suction line will be installed, the absolute atmospheric pressure defines the distance that the remaining absolute pressure can remove the liquid in an evacuated pipe by subtracting the suction loss value and is expressed in mSS.

ENPYt = Ha-hs-hb-hk

The values in the plant net positive absorption load formula expressed by the formula are as follows

- Ha: Atmospheric pressure mSS

- Hs:Distance between pump axis and liquid surface mSS

- Hb:Liquid evaporation pressure mSS

- Hk: Pipe friction losses and other resistances mSS

Condition for Non-Cavitation Operation of the Pump

If EnPYt > ENPY; the conditions in the suction plant installed raise the liquid above the level that the pump can suck.

What is Cavitation? What are the Negative Effects?

Cavitation, which is possible to encounter even in the human body, occurs in all systems with pressure and speed change. Especially problems in joints are common.

As the ambient temperature increases and the evaporation temperature decreases, the water vapor and bubble in the system produces a cold boil.

In pumps, the lowest pressure occurs at the impeller inlet and is collected here. We can list the effects of cavitation as follows.

- Cavitation is due to pressure drop and can be prevented if controlled.

- Occurs in the liquid phase and is not observed in the solid, gaseous phase

- Shortens pump life and causes noise

What is Cavitation? Causes

Cavitation occurs when there is a problem with atmospheric pressure. The causes may be the following.

- Atmospheric pressure on the pump and turbine may be low and this is why cavitation occurs.

- Possibility of air or gases dissolved in the liquid

- The suction line may be long or the suction valve is closed

- Flow rate may be above standards

- Cavitation may occur if suction line resistance is high

Problems Caused by Cavitation

Loss of performance in the pump system is the most serious problem. Noise occurs as a result of cavitation and reduces pump operating efficiency. In addition to noise, vibration problems come along with it. It can cause wear problems and loss of fluid properties within the system.

How to recognize cavitation in a pump

The best way to recognize the presence of cavitation inside the pump is to evaluate pressure differences. If the measured pressure at any point in the fluid is equal to or less than the vaporization pressure, cavitation damage is likely.

In order to prevent cavitation problem in the pump, regular pressure testing and analyzing the operating conditions of the system and taking the necessary measures will increase the pump life.

Anti-Cavitation Coatings

In the 17th century, with the invention of the modern centrifugal pump, we face the problem of cavitation. And this problem is the most damaging factor for pumps. This problem can be eliminated by coatings applied to these surfaces, especially on low pressure surfaces.

As well as damaging the pump impeller and casing, it also causes serious damage to the pump bearings, wear rings and seals and causes excessive vibration.

For the impeller and other casing elements most affected by cavitation, it can be coated with material that withstands high pressure levels and harsh environments. With the help of polymer material, broken, worn, lost parts are repaired by rebuilding.

With the help of ceramic coatings, solutions can be provided for what is cavitation and what are the problems and erosion cavitation is prevented. To repair and prevent damage, solutions are produced with polymer repair filling solutions, ceramic additive coating and elastomeric application.

Some Cavitation Damage Patterns, Causes and Solutions

| Damage Model | Possible Causes | Possible Solutions |

| Initial region on the wing suction surface near the leading edge | Unfavorable flow distribution above the impeller. Blade inlet angles are excessive | Reduce blade entry angles Improve leading edge profile Reduce impeller entry diameter |

| The region of the wing near the leading edge on the pressure surface | Unsuitable leading edge profile Excessive flow rate | Reducing the flow rate Improving the leading edge profile Narrowing the profile on the pressure surface |

What is cavitation? We have included important topics such as what are the basic problems, please be sure to ask what you are curious about.

Click here for detailed information about water pumps. Click here for water pump prices.