What is a Vibration Motor and What Does It Do?

A vibration motor is an electric motor that performs the function of shaking or moving an object by creating mechanical vibrations.

Vibration motors generate centrifugal forces through high-speed rotation, which create vibrations in the device in which the motor is mounted. They can have different connection types, powers, speeds and sizes. The most common areas of use are:

- Concrete industry: Vibration motors are used in concrete mixing, pouring, compaction and molding. Vibration motors are required for homogeneous mixing of the concrete and to remove air bubbles. It is also important for the concrete to fully fit into the molds and take the desired shape. The vibration motors used in the concrete industry are usually Kem-P branded.

- Surface treatment industry: Vibration motors are used in the surface treatment industry for processes such as polishing, grinding, cleaning, sorting and classifying. Vibration motors used in the surface treatment industry are usually ERBA or VIBRA MOTOR branded.

- Food industry In the food industry, it is used in processes such as material handling, feeding, dosing, sieving and packaging. Vibration motors used in the food industry are generally Kampa branded.

The advantages of vibration motors are:

- Mechanical simplicity: Vibration motors have a simpler structure than other vibration generating systems. Vibration motors do not need additional parts such as belts, chains and gears.

- Easy installation: It can be easily mounted according to different connection types. Vibration motors with foot connection or flange connection can be preferred.

- Low maintenance cost: Thanks to their low energy consumption and long lifetime, they have low maintenance costs. Maintenance does not require lubrication or cleaning.

- Flexible operation: It can operate flexibly according to different frequency and amplitude settings. The operating parameters of the vibration motors can be controlled electronically.

Things to Consider When Making a Choice

- Type of application: When making the selection, a model suitable for the purpose of the application should be chosen. For example, high power and high speed should be selected for concrete compaction.

- Mounting method: When making the selection, a model suitable for the type of installation should be selected. For example, a model with flange connection should be selected for a vibration motor to be mounted horizontally or vertically.

- Power and speed: Power and speed values should be considered when selecting a vibration motor. Power and speed values determine the centrifugal force and vibration frequency to be produced by the vibration motor. Power and speed values should be selected according to the vibration intensity and speed required by the application.

- Size and weight: When selecting a vibration motor, attention should be paid to size and weight. Size and weight values determine the mounting area and carrying capacity of the vibration motor. The size and weight values should be selected according to the constraints of the application.

The vibration motor is an important electric motor used in many industrial applications. When choosing a vibration motor, it is necessary to choose a model suitable for the needs of the application. It is also important to choose reliable brands when choosing a vibration motor.

How does a vibration motor work?

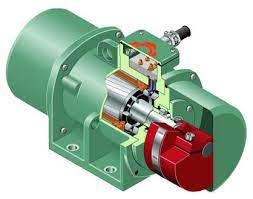

A vibration motor is an electric motor that converts electrical energy into mechanical vibration energy. The principle of operation is based on the principle of centrifugal force.

Centrifugal force is the tendency of an object to move away from the center while moving in a circular motion. The eccentric weights rotating in relation to the rotor shaft generate centrifugal force. These forces create vibrations in the device in which the motor is mounted.

The operating parameters of the vibration motor can be controlled electronically. The vibration intensity and speed produced by the vibration motor depends on the size, position and angle of the eccentric weights.

As the size of the eccentric weights increases, the vibration intensity increases. When the position of the eccentric weights is changed, the direction of vibration changes. When the angle of the eccentric weights is adjusted, the vibration frequency can be adjusted.

The vibration motor is an important electric motor used in many industrial applications. When making the selection, it is necessary to choose a model suitable for the needs of the application. It is also important to choose reliable brands when choosing a vibration motor.

Click here for detailed information about hardware installation. Click here for vibration motor prices.