What is a Stage Pump, How Does It Work? 5 Question and Answer

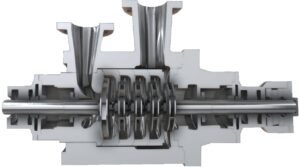

A stage pump is a type of pump used to transport water at high pressure. A cascade water pump consists of many small pumps connected to each other. Let’s get started.

Table of Contents

Each small pump increases the pressure by pushing the water towards the inlet of the next pump. In this way, the cascade pump can deliver water to the desired height or distance.

What are the Advantages of a Step Pump?

The cascade pump is more efficient and economical than single-stage pumps. It consumes less energy and generates less heat.

It takes up less space and is easier to maintain. Can be used to adjust the flow rate and pressure of water.

What are the Areas of Use of the Gradual Pump?

Cascade water pumps are used in many areas such as water supply, irrigation, fire extinguishing, industrial processes, cooling systems, hydroelectric power plants. It can be preferred wherever water needs to be transported with high pressure.

How to Choose a Step Pump?

There are some factors to consider when choosing a progressive water pump. These are:

- Flow rate of water: It means the volume of water transported per unit time. Cascade pumps can be of different sizes depending on the flow rate.

- Water pressure: It means the difference between the inlet and outlet pressure of the water. It can have a different number of stages depending on the pressure.

- Water temperature: It means the difference between the inlet and outlet temperature of the water. Cascade pumps according to temperature can be made of different materials.

- Water quality: This refers to factors such as solids in the water, corrosion, abrasion. Depending on the quality, it can have different protection systems.

You can contact us for more information about step pumps. We will help you choose the most suitable pump for you.

What Does Pump Step Mean?

The stage in the pump is a feature that determines the pressure and flow rate values of the pump. Pump stages are the number of impellers inside the pump.

Each impeller increases pressure and flow rate as it transfers water to the next stage. The pump stages affect the performance and efficiency ofthe pump.

The number of pump stages varies according to the application in which the pump will be used. For example, more stages are used in applications requiring high pressure, while fewer stages are used in applications requiring low pressure. The number of pump stages also affects the size, weight, cost and energy consumption of the pump.

When determining the number of pump stages, besides the pressure and flow rate values of the pump, factors such as water properties, pipe diameter, pipe length, pipe losses, height difference should also be taken into account. Pump selection programs can be used to calculate these factors.

To increase or decrease the number of pump stages, the number of impellers inside the pump is increased or decreased. For this operation, the pump must be disassembled and reassembled. Care must be taken not to damage the pump during this process.

Changing the number of pump stages changes the performance and efficiency of the pump. For this reason, it should be checked whether the pump is suitable for the operating conditions. Otherwise, the pump may malfunction or operate inefficiently.

After answering the question what does a stage in a pump mean, we would like to present some questions and answers on the subject. These questions and answers may help you to learn more about stepping in a pump.

Questions and Answers

Question 1: What happens if the number of pump stages is too large?

Answer 1: The higher the number of pump stages, the higher the pressure and flow rates of the pump. However, this also increases the size, weight, cost and energy consumption of the pump.

Question 2: What happens if the number of pump stages is too small?

Answer 2: The fewer the number of pump stages, the lower the pressure and flow rates of the pump. However, this also reduces the size, weight, cost and energy consumption of the pump.

Question 3: How can I determine the number of pump stages?

Answer 3: In order to determine the number of pump stages, it is necessary to know the pressure and flow rate values of the application where the pump will be used.

It is also necessary to take into account factors such as water properties, pipe diameter, pipe length, pipe losses, height difference. Pump selection programs can be used to calculate these factors.

Question 4: What should I do to change the number of pump stages?

Answer 4: To change the number of pump stages, it is necessary to increase or decrease the number of impellers inside the pump. For this operation, the pump has to be disassembled and reassembled. Care must be taken not to damage the pump during this process.

Question 5: What should I do after changing the number of pump stages?

Answer 5: After changing the number of pump stages, it is necessary to check whether the pump is suitable for the operating conditions. Otherwise, the pump may malfunction or work inefficiently.

Click here for horizontal stage pump prices. Click here for vertical stage pump prices. Click here for detailed information about water pumps.