What is a Magnetic Pump? Acid Pump

What is a magnetic pump? A pump designed to pump toxic and other hazardous liquids without the use of mechanical seals.

Table of Contents

What is a magnetic pump? A type of pump that is powered by the use of the science of magnetism rather than electricity from an external source.

What is a magnetic pump? It is energy efficient and requires no shaft seals or oil seals for operation.

What is a magnetic pump? It transfers various liquids, including acids, water and oils.

Since magnetic pumps do not have a mechanical seal, there is no possibility of dangerous chemical leakage or overheating of the pump due to a blockage.

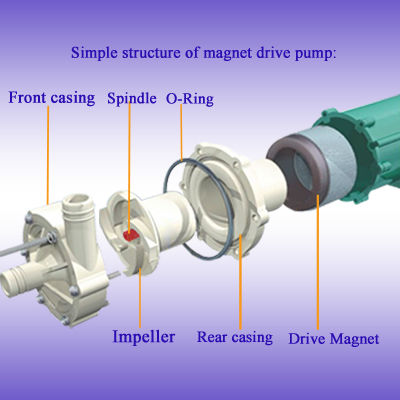

The general characteristics of magnetic pumps include a rotating impeller in a closed housing supported by a magnetic field, generated by magnets.

The rotation of the impeller generates a force that feeds liquid through and out of the pump’s casing. The main purpose of the pump is to conserve energy and motion in a liquid.

Magnetic pumps have magnets attached to the impeller and motor. The permanent magnets are connected to the drive assembly of the pump. The drive magnet, the magnet that drives the inner rotor, is connected to a second shaft driven by the motor.

When the motor is switched on, it turns its magnet. The magnetic force from the motor’s magnet causes the magnet in the propeller to turn and rotate the propeller.

What is a magnetic pump? It is a centrifugal pump, which means that the liquid pumped through the system exits the pump at a different point from where it is sucked in. The rotation of the impeller causes the fluid to increase in energy and the pressure at which the fluid discharges from the pump increases. This increase in pressure is what prevents the fluid from moving.

What is a Magnetic Pump? Working Principle

A magnetic pump uses a balanced magnetic field to generate the rotation of the fluid impeller. Unlike a conventional centrifugal pump with a direct drive linkage between the impeller and motor, a mag drive pump eliminates the direct drive mechanism and replaces it with a magnetic field.

An outer magnetic bell housing is mounted on the end of the pump shaft. This outer bell is aligned to the outside of the rear housing. The pump impeller is connected to a smaller magnet assembly and goes to an inner shaft and bushing assembly.

(The fluid end parts are all isolated inside the fluid head of the pump without the need for a mechanical seal.) The small magnet assembly is mounted in the center of the magnetic field of the outer bell housing.

Although these two magnet assemblies are separated by a liquid barrier, the magnetic fields are aligned. When the pump motor is started, the outer bell housing starts to rotate.

As the outer bell spins, the rotating magnetic field affects the inner impeller magnet. When the two magnets start to come together, the impeller starts to rotate and displace the liquid.

What is a Magnetic Pump? Why is it used?

With a standard centrifugal pump, some kind of seal is required to prevent the pumped fluid from leaking around the pump shaft, especially if it is at high pressure. There are three main options:

- Packing: a packing material compressed around the pump shaft is held in place in the opening in the casing (stuffing box) and compressed by a gland nut which is tightened as the packing material wears or stops.

- Lip seal or O-ring : A rubber or plastic ring fits around the drive shaft and is held in place in a groove in the pump casing.

- Mechanical seal: The mechanical seal consists of two parts: a component fixed to the pump casing and a component rotating on the pump shaft. The faces of the two components are machined to be flat and smooth and are spring-loaded so that they are pressed together. This is the most effective option for reducing leaks, but can be expensive and difficult to install.

Nevertheless, these 3 items are not ideal to prevent leakage. Even if it prevents fluid leakage, it may leak gas. In fact, sealing is important to maintain a small leakage to lubricate and cool the magnetic pump shaft.

In some cases, it is necessary to inject a lubricant to prevent overheating and this introduces the possibility of contamination of the pumped liquid.

A pump seal requires monitoring and frequent maintenance to prevent excessive leakage, especially when the pumped liquid contains abrasives. All leaking liquids must be safely contained and disposed of.

If the liquid is also toxic, flammable, radioactive or environmentally damaging, the possibility of leakage, even small ones, can be extremely dangerous. Leakage is one of the main causes of pump failure or shutdown, and maintenance of seals and packing materials is expensive and time-consuming.

Environmental concerns and legislation have driven industry to implement cleaner pumping technology. The magnetic pump contains the pumped liquid completely inside the pump casing.

It only has a hermetic seal (a fixed gasket or O-ring) that is not subject to abrasion from moving parts. It is therefore ideal for applications where leakage cannot be tolerated on safe floors or where recovery and treatment costs are low.

What is a Magnetic Pump? Where is it used?

It is generally used when the product being pumped is of a corrosive nature or when leakage of this product has the potential to harm operators or the environment.

In particular, it should be used to transfer the following chemicals.

- Hidroklorik asit

- Metan

- Sodyum sülfat

- Sodyum hidroksit

- Sodyum hipoklorit

- Sülfürik asit

Some typical applications where these products are used are as follows.

- Tanker Unloading

- Batch Chemical Processing

- Specialty Chemicals

- Column reflux

- Reactor Feed

What is a Magnetic Pump? What are the Prices in Which Ranges?

As always, prices vary according to pressure and flow rate in these pumps. As Kampa, we try to serve with the most affordable prices in all products.

In this article, we have touched on the main topics such as what is a magnetic pump, how it works, why it is used, what are its features, in which ranges are the prices. If you send us any questions that are not explained above, we will be happy to answer them by commenting below. You can order the best-selling chemical pump Cacheng CMP 15 R from our site.

You can contact us on our Kampa Whatsapp line to get information and suggestions about the magnetic pump. Click here for information on liquid transportation with chemical pump

Don’t forget to share if you found it useful .