What are Industrial Fan Types, Place of Use

Industrial fan is a device used in many areas such as ventilation, cooling, heating, drying, dust collection. Industrial fans are divided into different types according to their working principles, structure, capacity and usage areas.

Table of Contents

In this article, we will introduce industrial fan types and explain which fans are preferred in which sectors.

What are Industrial Type Fan Types?

Industrial type fans are generally divided into two main groups: Axial fans and radial fans. Axial fans are fans that provide air flow parallel to the axis on which the propeller rotates. Radial fans are fans that provide air flow perpendicular to the axis on which the propeller rotates.

Axial Fans

Axial fans are fans that provide air flow parallel to the axis on which the impeller rotates. Axial fans are used in low pressure and high flow ventilation systems.

The advantages of axial fans include low energy consumption, easy installation and maintenance, and quiet operation. The disadvantages of axial fans are low pressure, noisy when operating at high speed and loss of efficiency in dusty environments.

Axial fans are divided into four subgroups according to their construction: Blade type axial fans, tunnel type axial fans, wall type axial fans and roof type axial fans.

Blade Axial Fans

Blade axial fans are axial fans whose impeller is shaped like a wing and the blade angle can be adjusted. It can work efficiently by changing the blade angle according to the flow and pressure requirement. It is used for ventilation in large volume areas such as industrial facilities, warehouses, greenhouses, sports halls.

Tunnel Type Axial Fans

Tunnel type axial fans are axial fans whose impeller is located in a tunnel-shaped body and provide ventilation in tunnels. Tunnel type axial fans are used in high flow and medium pressure ventilation systems.

Advantages of tunnel type axial fans include high efficiency, long life, easy installation and maintenance. The disadvantages of tunnel-type axial fans are that they are noisy when operating at high speed and lose efficiency in dusty environments.

Tunnel type axial fans are used for ventilation in underground tunnels such as subway tunnels, highway tunnels, mines.

Wall Mounted Axial Fans

Wall-mounted axial fans are axial fans whose impeller is mounted on the wall and provides air flow through the wall. Wall mounted axial fans are used in low flow and low pressure ventilation systems.

Advantages of wall-mounted axial fans include low energy consumption, easy installation and maintenance, and quiet operation. The disadvantages of wall-mounted axial fans are low pressure, noisy when operating at high speed and loss of efficiency in dusty environments.

Wall-mounted axial fans are used for ventilation in small and medium-sized industrial plants, workshops, offices, shops, restaurants, etc.

Roof Type Axial Fans

Roof type axial fans are axial fans whose impeller is mounted on the roof and provides air flow over the roof. Roof type axial fans are used in low flow and low pressure ventilation systems.

The advantages of roof type axial fans include low energy consumption, easy installation and maintenance, and quiet operation. The disadvantages of roof type axial fans are low pressure, noisy when operating at high speed and loss of efficiency in dusty environments.

Roof type axial fans are used for ventilation in small and medium-sized industrial facilities, warehouses, greenhouses, sports halls, etc.

Radial Fans

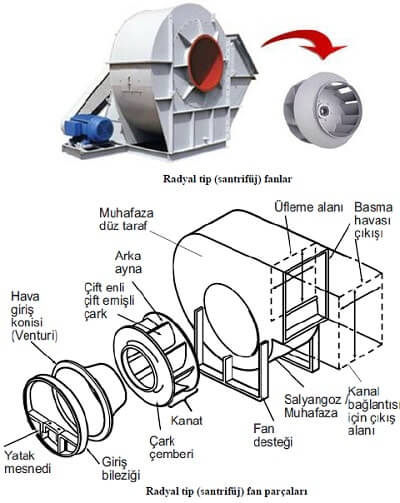

Radial fans are fans that provide air flow perpendicular to the axis on which the impeller rotates. Radial fans are used in high pressure and medium flow ventilation systems.

The advantages of radial fans include high pressure and efficient operation in dusty environments. The disadvantages of radial fans include high energy consumption, difficult installation and maintenance, and noisy operation.

Radial fans are divided into three subgroups according to their construction: Centrifugal fans, turboventilators and jet fans.

Centrifugal Fans

Centrifugal fans are radial fans whose impeller rotates with centrifugal force and directs the air flow radially. Centrifugal fans are used in high pressure and medium flow ventilation systems.

The advantages of centrifugal fans include high pressure and efficient operation in dusty environments. The disadvantages of centrifugal fans include high energy consumption, difficult installation and maintenance, and noisy operation.

Centrifugal fans are used for ventilation in industrial plants, factories, laboratories, hospitals, etc.

Turboventilators

Turboventilators are radial fans with a turbo-shaped impeller that directs the air flow radially. Turboventilators are used in high pressure and high flow ventilation systems.

The advantages of turboventilators include high pressure and high flow rate. The disadvantages of turboventilators include very high energy consumption, very difficult installation and maintenance, and very noisy operation.

Turboventilators are used for ventilation in large-scale industrial plants, power plants, iron and steel factories, etc.

What should we pay attention to when choosing?

When choosing an industrial fan, we should choose a model that is suitable for the characteristics of the ventilation system we need. Some of the criteria we should pay attention to when choosing an industrial type fan are as follows:

- Size and shape of the area to be ventilated

- Physical conditions of the environment such as temperature, humidity and dust

- Chemicals, gases or particles in the environment

- Desired air flow rate and pressure

- How and where to install the fan

- Energy consumption and efficiency of the fan

- Noise level and vibration of the fan

- Maintenance and cleaning of the fan

Where should we buy it?

When buying an industrial fan, we should buy from a reliable and quality brand. Here are some points we should pay attention to when buying:

- Documentation of the technical specifications of the fan

- Fan warranty period and service

- Testing and approval of the fan

- Fan installation and commissioning

- Instructions for use of the fan and training

What should we pay attention to when using industrial type fans?

We must ensure that the fan works efficiently and safely. Here are some of the things we should pay attention to when using industrial fans:

- Regular maintenance and cleaning of the fan

- Operating the fan at the appropriate speed and direction

- Prevention of fan overload or heating

- Protection of the fan from harmful factors such as dust, moisture, corrosion or impact

- Not touching or blocking the fan while it is running

Ventilation is a device that helps us in many areas we need. With the right choice, purchase, use and maintenance, they can work long-lasting and efficiently. You can contact us for more information about industrial fans.

What are the Different Uses of Industrial Fans?

Industrial fans are a device used to move large volumes of air. It helps us in many areas where we need ventilation. What are the different uses of industrial type fans? Here are some examples:

- Factories: Used in factories to improve the efficiency and quality of the production process. It controls the temperature, humidity, dust and gas of the environment in factories. It also protects the comfort and health of workers in factories.

- Warehouses Used to improve the storage conditions of products in warehouses. It prevents spoilage, mold, rot or damage to products in warehouses. Industrial fans save energy in warehouses.

- Workshops Industrial fans are used in workshops to ensure work safety and quality. Industrial fans clean, cool and dry the air in workshops. Industrial fans ensure that employees in workshops are comfortable and work efficiently.

- Greenhouses Industrial fans are used for the growth and development of plants in greenhouses. Industrial fans provide the air circulation, temperature and humidity balance that plants need in greenhouses. Industrial fans increase the resistance of plants against diseases and pests in greenhouses.

- Sports halls Industrial fans are used in gyms to improve the performance and comfort of athletes. Industrial fans freshen, cool and dry the air in gyms. Industrial fans reduce sweating and fatigue of athletes in gyms.

- Restaurants Industrial fans are used in restaurants to increase customer and employee satisfaction. Industrial fans clean, freshen and deodorize the air in restaurants. Industrial fans preserve the flavor and freshness of food in restaurants.

What should we consider when choosing an industrial fan?

When choosing an industrial fan, we must choose a model that is suitable for the characteristics of the ventilation system we need. Here are some of the criteria we should pay attention to when choosing an industrial fan:

- Size and shape of the area to be ventilated

- Physical conditions of the environment such as temperature, humidity and dust

- Chemicals, gases or particles in the environment

- Desired air flow rate and pressure

- How and where to install the fan

- Energy consumption and efficiency of the fan

- Noise level and vibration of the fan

- Maintenance and cleaning of the fan

Where should we buy industrial fans?

When buying an industrial fan, we should buy from a reliable and quality brand. Here are some points to consider when buying an industrial fan:

- Documentation of the technical specifications of the fan

- Fan warranty period and service

- Testing and approval of the fan

- Fan installation and commissioning

- Instructions for use of the fan and training

Click here for industrial type fan prices. Click here for detailed information about industrial type fans.