Fan Usage Areas and Types Better Content

A fan that provides air flow by creating a pressure difference. Its moving element, the blade, gives it kinetic energy. Let’s examine the fan usage areas.

Table of Contents

The ratio of these static and kinetic energies to each other depends on the characteristics of the fan.

Fans are like pumps, but unlike pumps, they are equipment that pressurizes the gas instead of the liquid and allows it to be transferred.

Fans are the most important equipment used in the ventilation of residences, workplaces and especially collective living spaces as well as air and gas suction and discharge functions required by industrial processes.

Blowers and compressors, like fans, are equipment that allows air to be pressurized and transferred. However, while fans can transfer air at higher flow rates but at lower pressures, blowers and compressors can reach very high pressure values.

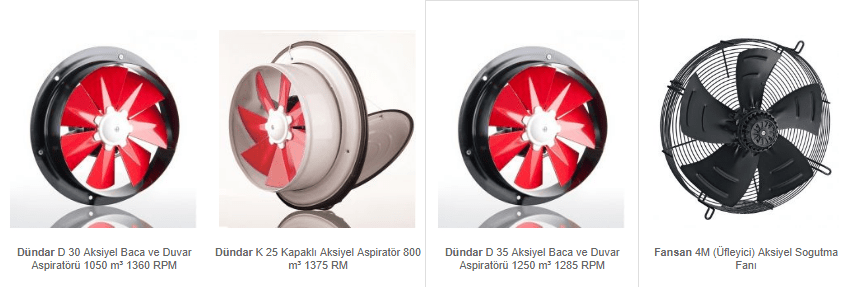

Two types of fans are generally used in applications.

Fan Types and Fan Usage Areas

- Axial fans: These are fans in which air flows parallel to the axis of rotation, but can be used in environments where the resistance to flow is very small. They are used in ambient ventilation processes such as taking air from outside and transferring it inside.

- The direction of the air is determined by the shape of the fan blades and the direction of rotation. In this type of fan, the air is sucked in from the side where the motor is located and exhausted from the other side. Due to the low pressure high volume air flows they create, axial fans are the most suitable for general purpose applications.

2.Radial fans: These fans have a rotating impeller like the pump and a spiral housing in which the impeller is located. Air or gas enters from the center parallel to the axis, is pressurized and transferred to the ducts tangentially around the impeller and blown out of the blowing mouth.

These fans are the basic equipment used in dust containment, ventilation and cooling systems with duct applications in industrial plants.

–Radial Fans with Forward Rotating Curved Blades: The number of blades in these fans is more than other types of propellers. They are useful for low and medium pressure fans.

These fans are used for fixed operating points. Motor power increases rapidly for changing speed and pressure values. Not suitable for abrasive materials other than air. Since the propeller blades are very close to each other, they are easily contaminated and damaged in oily and dusty environments.

– Radial Fans with Reversed Curved Edge: The number of propeller blades used in these fans is small. Since they are not affected much by impacts and adverse weather, there is no such situation as excessive strain on the engine.

For high flow rate and pressure, it is necessary to increase the number of revolutions very much. Therefore, they must have a robust structure. Click here for detailed information about ventilation fans and their usage areas. Click to ventilation fans prices.