What is a Pneumatic Valve and How Does It Work? All Details! 2025

Optimize your automation system with detailed information about what a pneumatic valve is, how it works, its types and industrial usage areas.

Table of Contents

Pneumatic Solenoid Valve: Indispensable for Industrial Automation

Pneumatic systems are one of the most critical components of industrial automation and pneumatic valves play a crucial role in their operation. In this article, we will examine in detail what pneumatic control valves are, their types, working principles and their place in industrial applications.

What is a Pneumatic Valve?

It is a mechanical or electromechanical device that controls the flow of compressed air. The answer to the question of what is a pneumatic pressure relief valve can be summarized as the fact that this device regulates the direction, pressure and flow rate of the air and ensures the operation of pneumatic systems. It is widely used especially in factory automation, robotic systems and packaging lines.

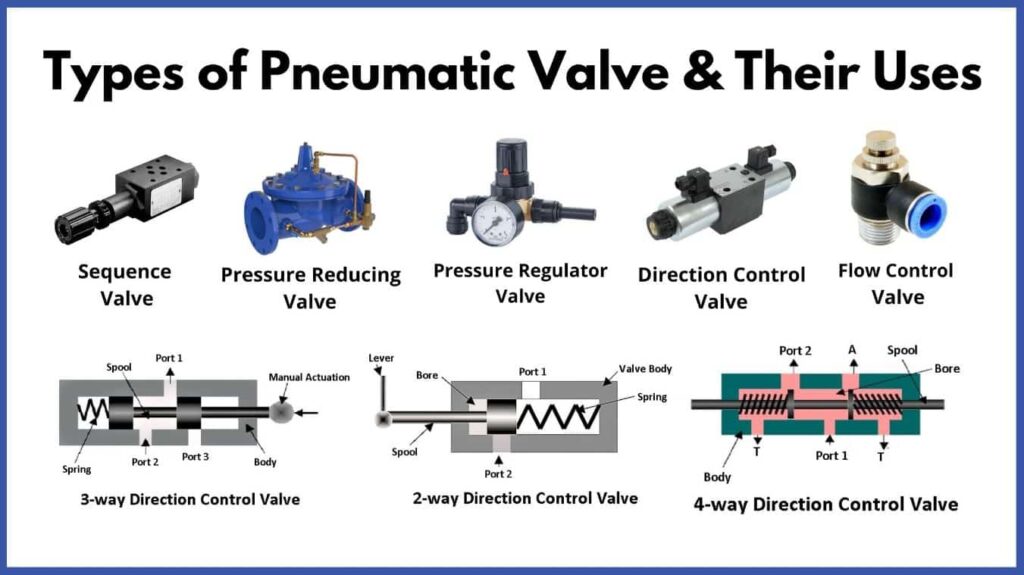

Types of Pneumatic Valves

Pneumatic shuttle valves vary according to their function and design. Pneumatic valve types include directional control valves, pressure control valves, directional control valves and flow control valves. The main models of pneumatic valves are:

- Directional Control Valves Directional control valves determine the direction of air flow. For example, it allows a cylinder to move forward or backward. This group includes models such as 5/2 pneumatic valves and 3/2 pneumatic valves.

- Pressure Control Valves These valves are used to regulate the air pressure in the system. By keeping the pressure at a constant level, it ensures efficient operation of the system.

- Flow Control Valves Flow control valves adjust the speed of movements in the system by controlling the air flow rate. Pneumatic proportional valve is an example of this type of device.

- Safety Valves Safety valves prevent accidents by activating when dangerous pressure levels are reached in the system.

- Pneumatic Solenoid Valves Pneumatic solenoid valve is a type of electrically controlled valve. It is widely preferred in automation systems with its fast and precise control feature.

- Pneumatic flow control valve Islands Valve groups in which more than one manual pneumatic valve is brought together and used in a single structure. This structure offers a more compact and effective solution.

Working Principles of Pneumatic Valves

Pneumatic valves are usually actuated by a spring mechanism, a coil or a manual trigger. Valves with electric actuation systems integrate with control panels and adapt to automation systems.

The operating principle of the pneumatic control valve is basically as follows:

- Input Port The section where air enters the valve.

- Output Port The section where controlled air flow is provided.

- Exhaust Port The section where the used air is discharged from the system.

Materials Used in Air Valve

The materials used in its manufacture directly affect the durability and performance of the device. The valve body is usually made of stainless steel, aluminum or plastic.

Stainless steel valves are preferred in special applications such as the food and chemical industry because they are corrosion resistant. Plastic valves, on the other hand, stand out with their light weight and are used in low pressure systems.

Industrial Usage Areas of Electro Pneumatic Valves

It has a very wide range of applications. The main areas of use are:

- Factory Automation: Used to control robotic arms and other moving equipment on production lines.

- Packaging Industry: Precisely regulates the air flow, ensuring the correct operation of packaging machines.

- Medical Devices: Valves are vital in respirators and other medical equipment.

- Energy Sector: Used for flow control and safety measures in power plants.

- Agricultural Technologies: Provides efficiency in applications such as planting and irrigation by controlling air flow in agricultural machinery.

- Automotive Industry: Pneumatic directional control valves control the movement of robotic systems used in vehicle assembly lines.

Advantages and Disadvantages of Pinomatic Valves

Their advantages make them indispensable in industry. However, some disadvantages should also be considered:

Electronic Pneumatic Valve Advantages

- High efficiency thanks to fast response time.

- Long lasting with its durable structure.

- It offers an environmentally friendly system; the air used can be recycled back into nature.

- It offers a wide range of products suitable for different application areas.

Electro-Pneumatic Valve Disadvantages:

- Compressed air requires energy for its production.

- May cause energy loss in low efficiency systems.

- There may be performance limitations in applications requiring high precision.

Maintenance of Air Valves

Regular maintenance is necessary for trouble-free operation. The maintenance process consists of the following steps:

- Cleanliness: Air filters and ports should be cleaned regularly to prevent clogging of the valves.

- Leakage Control: Leaks cause energy loss, so gaskets and connections should be checked.

- Spare Part Replacement: In case of wear, repairs should be made using original spare parts.

- Performance Testing: After maintenance, the performance of the valves should be tested to ensure proper operation.

What to Consider When Choosing a Directional Control Valve?

It directly affects system performance. Therefore, attention should be paid to the following factors:

- Pressure and Flow Requirements: The air pressure and flow rate required by the system are the primary criteria for valve selection.

- Valve Material: Valves made of material suitable for the working environment should be preferred.

- Ease of Installation and Maintenance: Models that are easy to install and require low maintenance provide cost advantages in the long term.

- Automation Compatibility: Integration of the valve into the automation system is important.

- Manufacturer Assurance: Long-term performance can be ensured by choosing products from trusted brands.

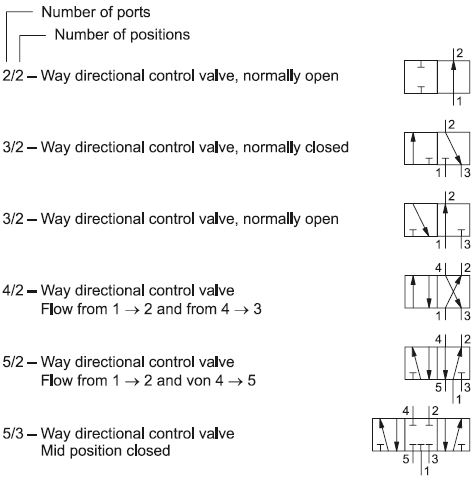

Pneumatic Valve Symbols

Valve symbols are standard graphic representations that usually visualize the functions and connection structures of valves. These symbols are critical for understanding and designing pneumatic system schematics.

The following details about symbols can be added:

- Directional Control Valve Symbols:

- 3/2 Directional Control Valve: Contains three ports and two states; usually one inlet, one outlet and one exhaust port.

- 5/2 Directional Control Valve: Includes five ports and two states; used for more complex systems.

- Pressure Control Valve Symbols:

Symbols for valves that control pressure usually include spring or other mechanical control indicators. - Flow Control Valve Symbols:

Symbols denoting valves that limit or regulate air flow. - Solenoid Control Symbols:

Electrically triggered valves are indicated by coil symbols and electrical connections.

Conclusion

The pneumatic valve is one of the cornerstones of industrial automation. With the right choice and use, both system performance increases and energy savings are achieved.

For pneumatic quick exhaust valves to operate with high efficiency, regular maintenance and control is of utmost importance. Understanding the differentiating role of pneumatic valves in industrial applications can be the key to success. Click here for detailed information about pneumatics.