What is a Centrifugal Pump?

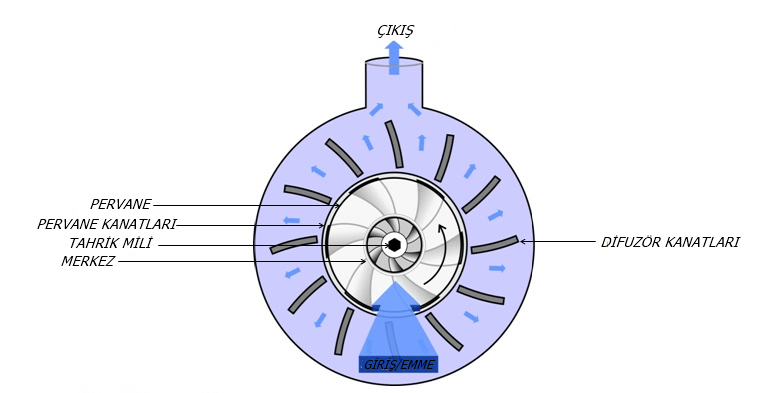

Centrifugal pumps are mechanical devices that move liquid by means of the energy generated by the rotation between the impellers.

The liquid enters the rapidly rotating impeller along its axis and is ejected by centrifugal force through the impeller’s vane tips. The movement of the impeller increases the velocity and pressure of the liquid and directs it towards the pump outlet.

How Centrifugal Pumps Work

The impeller is the most important part of irrigation pumps. It consists of a series of curves. These are like a closed impeller between two disks.

The liquid enters the impeller axis, exits through the vanes. The impeller is connected to the motor through a drive shaft.

When the motor starts, the impellers start to rotate at high speed. With the rotation of the impellers, the liquid is accelerated from the impeller vanes to the pump body.

There are two basic designs of the pump casing. The aim of both designs is to convert the liquid flow into a pressure-controlled discharge.

Volute Type Centrifugal Pump

Jet type Pump

Their basic working principles are similar, but snail pumps can suction up to 6 meters at most, while jet pumps can suction up to 9 meters because they contain injectors and diffusers.

Volute type centrifugal pumps are mostly used in field and garden irrigation. Since jet pumps are deeply suctioned, they can pump more pressure than volute pumps.

Usage Areas of Centrifugal Pumps

Centrifugal pumps are widely used for pumping water, solvents, organics, oils, acids, bases and any ‘thin’ liquids in industrial, agricultural and domestic applications.

In fact, there is a suitable water pump design for almost every application involving low viscosity fluids.

Conclusion;

A centrifugal pump works by transferring rotational energy through one or more phase-driven rotors, called impellers. The movement of the impeller increases the speed and pressure of the liquid and directs it to the pump outlet.

Centrifugal pump designs offer cost-effective solutions for pumping fluids such as water, solvents, chemicals, and light oils.

Things to Consider When Buying a Water Pump;

-Use Area

– Landing Depth

-Compression Height

-Distance to transfer the liquid

-The amount of liquid to be pumped,

Kampa website pumps category, you can call our call center to find the most suitable products for you, get technical information and advice from our expert staff who have been serving on ventilation and irrigation systems for many years.

Centrifugal pumps are a cornerstone of fluid transfer across countless industries, from supplying clean water to homes to powering complex industrial processes. Understanding what a centrifugal pump is, and what it is used for, is crucial for anyone involved in engineering, manufacturing, or maintenance.

Essentially, a centrifugal pump is a type of pump that uses a rotating impeller to increase the pressure and flow rate of a fluid. This means that the centrifugal pump motor rotates the impeller, creating centrifugal force that pushes the fluid outward, increasing its kinetic energy, which is then converted to pressure. Sometimes, you might encounter slight misspellings like “centrifigual pump” or variations like “centrifugaal pomp” (Dutch).

The centrifugal pump define is fairly straightforward: it’s a rotodynamic pump that uses centrifugal force to move fluids. When someone asks, “centrifugal pump meaning,” they are often looking for a concise explanation of this process. The centrifugal pump means efficient fluid movement through kinetic energy conversion.

Knowing centrifugal pump uses is essential when selecting the right pump for a specific application. Centrifugal pumps are used for a wide variety of applications, and the centrifugal pump is used for tasks like water supply, irrigation, sewage treatment, and chemical processing. The term “centrifugal water pump” or “centrifugal water pumps” specifically refers to pumps designed for water-based applications.

In essence, centrifugal pumps meaning is rooted in their design and function. The “centrifugal type pump” is a reliable and versatile solution for many pumping needs. However, it’s important to select the right pump based on the specific application requirements to ensure optimal performance and efficiency. Whether you are dealing with a small centrifugal water pump for domestic use or a large industrial unit, understanding the principles behind centrifugal pumps is key to successful operation and maintenance.

You can reach Turkey’s leading brands such as Wilo, Sumak, Pedrollo, Leo.

You can get all spare parts for your pumps from Kampa Ventilation and Irrigation Systems regardless of the brand.

If your pump has any malfunction, you can send the product to the technical service and have it repaired and maintained.

Click here for information about centrifugal pumps. Do you have any other questions?

Is there anything left unmentioned?

You can specify by commenting…