What is a Barrel Pump? How Does It Work?

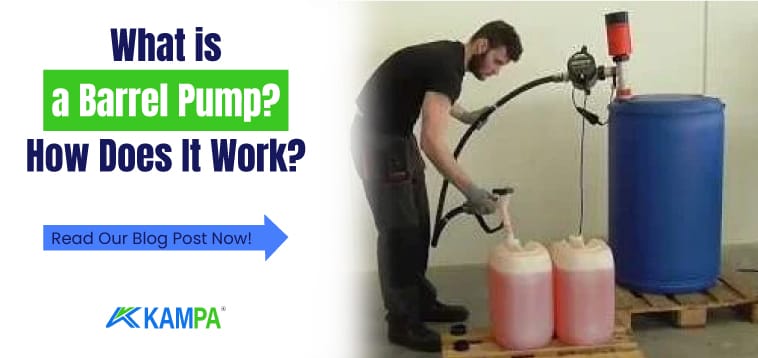

A barrel pump is a type of submersible pump with long pipes for transferring fluid from a closed vessel. The transfer is done by immersing the pump pipe in the closed vessel.

The most important difference of barrel pumps from other liquid pumps is that the pump motor remains outside the fluid. The liquid transfer process starts with the rotation of the fan at the end of the pipe inside the barrel as a result of the motor drive.

The closed container may contain acidic, basic, alkaline, corrosive, aggressive, flammable and flammable fluid or liquid soap, honey, chocolate, molasses, cream, glue, jam, shampoo, paint, etc.

These types of fluids are generally taken from barrels, containers, drums, IBC tanks and other containers and stored according to the area of use in the enterprise. Naturally, the fluid used as an additive is not exhausted in one go.

Even if it is consumed, this process is done by tipping the barrel, but this is inefficient in terms of worker health or product consumption and pollution. All these negativities are eliminated with the help of a barrel pump.

Barrel unloading pumps can be air, manual, motorized and electric depending on the application point. There are also SS316i Polypropylene and PVDF body types depending on the chemical to be transferred.

Barrel pumps have FDA (Food and Drug Administration) certificates required for food and pharmaceutical companies.

How Does a Barrel Pump Work?

The main purpose of barrel pumps is to use the purchased chemical only when needed. It usually consists of two different components. The pump pipe and the pump body inside. The pipe, which is immersed in the barrel, delivers the fluid to the pump body positioned above the barrel.

The impeller inside the casing rotates with the force from the motor and a vacuum is created at the inlet of the pump pipe. Thanks to the vacuum, the fluid in the barrel is drawn and directed to the pump outlet.

Considerations in Barrel Type Pump Selection

Barrel pumps are selected taking into account the characteristics of the fluid used(viscosity, temperature), flow rate and material properties. Choosing a barrel pump is important for a healthy, hygienic and safe environment.

If it will be used for food, a stainless barrel pump is selected. If the fluid is flammable, corrosive or flammable, you should choose an ex-proof electric or air motorized barrel type pump.

Liquids with low viscosity, such as water, or honey with high viscosity are suitable for jam. It is very important to evaluate the viscosity.

Also, choose a product for the working pressure and discharge flow rate suitable for your needs. When purchasing the amount of liquid to be used at one time, you should prefer by looking at the product features.

Barrel Pump Accessories and Features

The most important part is the motor that creates the vacuum. There are pneumatic and electric types. If you have a business with flammable or explosive fluids, choosing a barrel type pump with an exproof motor minimizes the danger that may arise in the future. Make sure that it has Atex certificate.

Besides stainless steel barrel pumps, PVC, PP and PVDF materials are the most preferred barrel type pump materials. In addition to the casing materials, the feature of the shaft material in the pump tube should also be taken into consideration. It is manufactured with stainless steel or Hastalloy C material.

The barrel pump is easily integrated with many accessories. For flow control, a gun system, hose apparatus or suction filter can be installed. If the fluid mixture in the barrel is mixed, the mixture can be kept homogeneous by placing the mixer as an accessory to the barrel pump.

Industries where Barrel Pumps are used

It is most frequently used in the fuel sector, but it is also used in refining, paint, cement, chemistry, refinery, iron and steel or power plants. It is also increasingly used in the food sector. Its active use in the pharmaceutical and cosmetics sector is also increasing.

Cacheng Drum Transfer Pump Specifications

- Long lasting PP plastic material body with high strength,

- Motor with powerful suction/vacuum power,

- Part with strong sealing,

- Handle with non-slip plastic,

- Bottom suction hole to prevent clogging,

- It can be used to transfer diesel, motor oil, petrol, gas oil.

- Engine power: 1800 watts,

- Length: 124 cm,

- Immersion depth: 90 cm,

- Output:1.1/4”

- Flow rate: 150L/min,

- Head height: 6 meters,

- RPM:15000 rpm

- Types of liquids not recommended: Chemical solution, latex solution, paste solution, skim solutions.

Click Cacheng PP plastic barrel pump to buy the product. You can send a message to our Kampa Whatsapp line to get information about other types of manual, mechanical barrel pumps.

Click here for more information about pump types. Click here to review and purchase barrel pump prices.