How to Read the Pump Performance Curve?

There is more than one way to select an industrial pump and a large number of centrifugal pumps to choose from. The primary pump selection tool is the pump performance curve, called the characteristic curve.

If you are a person who needs to select a pump for a specific application and you want to ensure that your pump has a long service life running at maximum efficiency, you need to be able to read and understand a pump curve.

Pump Performance Curve Indicates Pump Capability

Since we get a lot of questions about how to use and read a pump performance curve, we decided to write this blog. Pump curves are data about the ability of a given pump to produce flow against a given head.

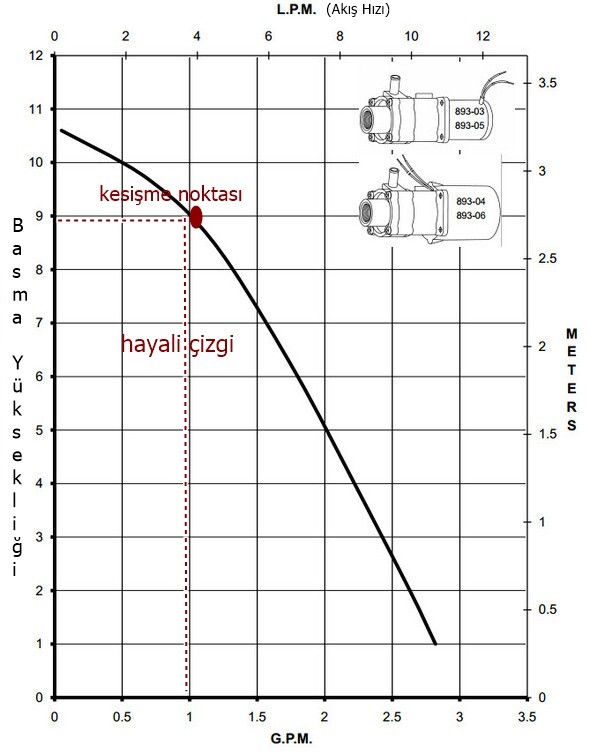

When reading a curve, the flow rate of the pump will be at the top and bottom and the thrust head will be on the sides. You will select the flow rate required by your application by drawing a line on the graph and then the desired head by drawing a line to the right. You will need to select a pump with a curve just above this point.

The slope curve you see in the center shows you how much flow and head the pump will deliver. On most pump performance curves, the Horizontal Axis you see is the flow (and is shown in Gallons in the US and Liters in other countries) and the Vertical Axis you see is the head of the pump (Feet for the US and Meters for other countries).

Pump Curve Graph

To read the curve, find a point on the horizontal axis that indicates GPM (Gallons Per Minute). Draw an imaginary line from the 1GPM line to the point where the 1GPM line hits the pump curve.

At the intersection of 1GPM and the curve, draw an imaginary line directly on the left axis and you will see that the number on the vertical axis is 9 meters.

Now you know that at 1GPM the pump in question will pump 9 meters. Instead of starting on the horizontal axis, you can also read from the vertical axis.

For example, if you want to know what flow the pump will produce at 10 feet, you need to find 10 feet on the vertical axis and draw an imaginary line to the right until you reach the pump curve. Then draw an imaginary line down. In this example, you reach 0.5GPM.

Technical Information for Reading Pump Performance Curve

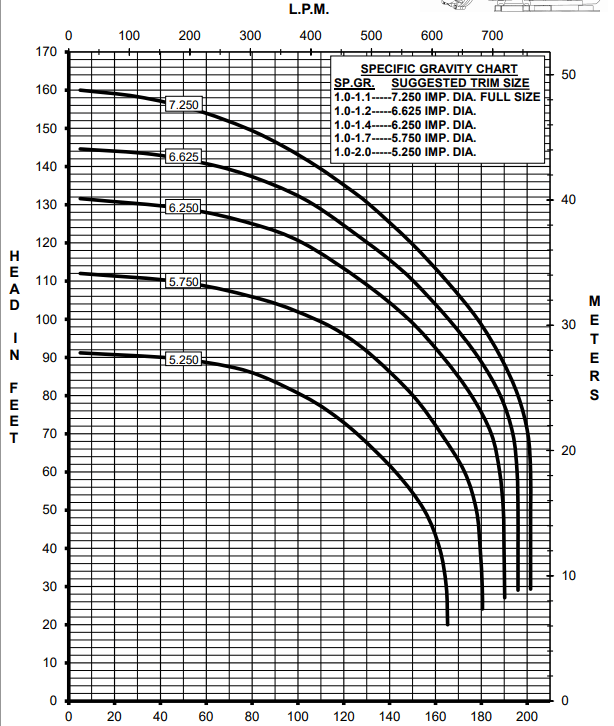

In the first example, you will see that there are two curves, one labeled 60HZ and one labeled 50HZ. You will need to read which one represents the power supply in your country (here in the USA it is 60HZ). On the second page you will find multiple pump performance curves with numbers on them. They show the length of the diameter of the pump impeller.

As the diameter decreases, the flow and head of the pump performance curve decreases. The standard impeller length is always the largest diameter, to obtain a smaller impeller size, the diameter must be specified. NOTE: The 50 hz pump curve flows less and the pump total pressure is lower than the 60 HZ curve as the pump motor will run slower.

- in the example you will find a list of available propeller diameters. On the top right you will see a specific gravity table with recommended cut sizes.

- You absolutely need to know the specific gravity of the liquid you need to pump. If the specific gravity is greater than 1.0 (weight of water), the pump may not be able to handle the liquid without changing the impeller diameter. You will find recommendations in the upper right corner of the curve designed to make the pump work for your application.

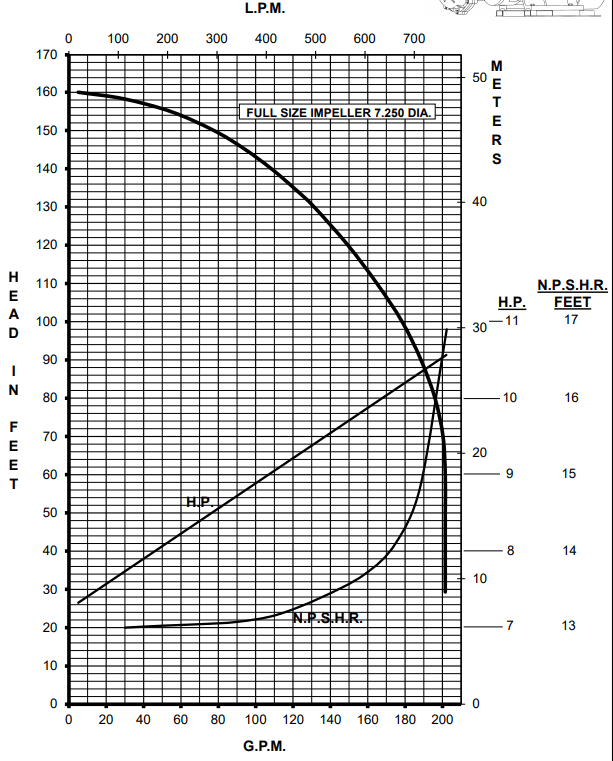

If you look at example 2, you will find a more detailed curve where the largest diameter is 7,250 inches. Using what you learned above, you will see that at 100GPM the pump pumps 144 meters. This curve will also tell you how much HP (horsepower) the pump will use and the required NPSHR (Net Positive Suction Head).

Find 100GPM at 144 meters and draw an imaginary line down from this point until you reach the HP line. At the intersection, draw an imaginary line to the right until it hits the vertical axis with HP on it.

In our 100GPM example at 144 meters you will see that the horsepower consumed is 8.8HP. If the specific gravity is something other than the weight of water, take the HP consumed and multiply it by the specific gravity. So if the specific gravity is 2.0.

Understanding pump performance is crucial for efficient operation and maintenance. Several tools are available to help engineers and operators visualize this performance, primarily through various curves and charts. Learning how to read a pump performance curve is fundamental. These curves, often referred to as pump charts or pump graphs, provide a visual representation of a pump’s capabilities, showing the relationship between flow rate, head, power consumption, and efficiency. You’ll find information on pump curve efficiency and understand how the pump operates at different points. Distinguishing between different types of pumps is also critical.

For example, the performance curve of a pump will differ significantly depending on the pump type. While centrifugal pumps are common, positive displacement pumps have their own unique characteristics. To understand performance curve of positive displacement pump, you will need to look at the positive displacement pump performance curve or the positive displacement pump characteristic curve. This curve might look different than the pump efficiency curve you see for centrifugal pumps. Similarly, the performance curve of a reciprocating pump will also display unique characteristics. It’s important to become familiar with how to read pump performance curves for different pump types, including how to read an ESP pump curve, for specialized applications. Examining a pump curve chart or even multiple pump graphs will help optimize the pump’s selection and prevent cavitation.

Understand Pump Characteristic Curve

A pump operator can quickly compare pumps by understanding the pump performance curve to determine the pump’s operating environment.

a) How fast can a given pump move liquid (gallons per minute)?

b) How much energy will a pump create to overcome losses in fluid delivery (total dynamic head per psi)?

c) How much horsepower will be required to operate (fuel or energy consumption)?

Click here for water pump models. Click here for detailed information about water pumps. Try our suggestions and let us know if they help.