Installation Pipe Diameters: Basics and Importance

The correct selection of pipe diameters in installation systems is vital to ensure efficient and economical operation of the system. Pipe diameters are one of the main factors affecting the movement ofwater or other fluids in the installation. For this reason, the calculation and selection of pipe diameters is considered one of the most important issues in installation engineering.

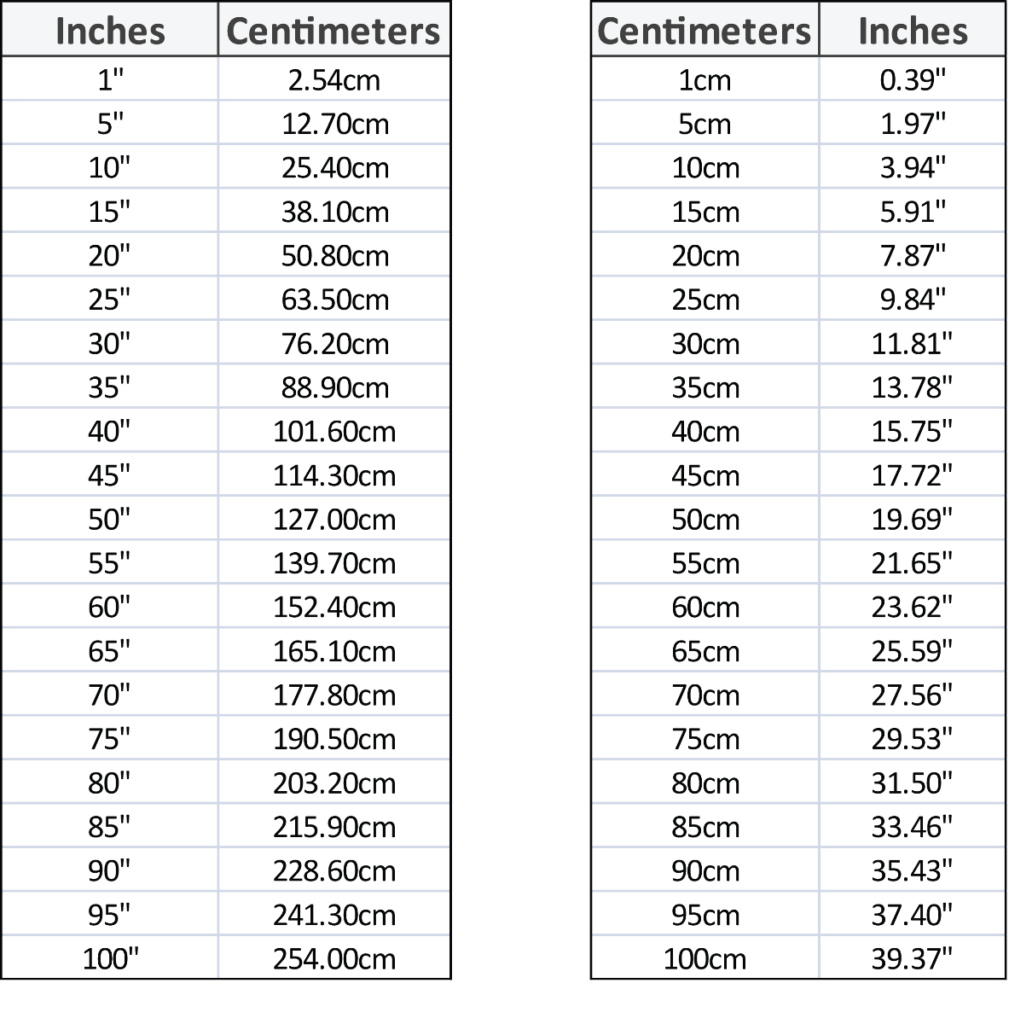

| Nominal Diameter(mm) | Outer Diameter(mm) | Wall Thickness(mm) | Inner Diameter(mm) | |

| 1/2” | DN 15 | 21,3 | 2,8 | 15,7 |

| 3/4” | DN 20 | 26,9 | 2,9 | 21,1 |

| 1” | DN 25 | 33,7 | 3,4 | 26,9 |

| 1.1/4” | DN 32 | 42,4 | 3,6 | 35,2 |

| 1.1/2” | DN 40 | 48,3 | 3,7 | 40,9 |

| 2” | DN 50 | 60,3 | 3,9 | 52,5 |

| 2.1/2” | DN 65 | 73,0 | 5,20 | 62,6 |

| 3” | DN 80 | 88,9 | 5,5 | 77,9 |

| 4” | DN 100 | 114,3 | 6 | 102,3 |

| 5” | DN 125 | 141,0 | 6,6 | 127,8 |

| 6” | DN 150 | 168,3 | 7,1 | 154,1 |

| 8” | DN 200 | 219,1 | 8,18 | 202,74 |

| 12” | DN 300 | 323 | 9,5 | 304 |

| 16” | DN 400 | 406 | 9,5 | 387 |

| 18” | DN 450 | 470 | 9,5 | 451 |

Determination of pipe diameters depends on many parameters such as flow rate, pressure loss, velocity and viscosity of the fluid. For example, water flow rate and pipe diameter calculation is a basic calculation method used in determining the required water flow rate in heating systems and sizing the pipe system.

In addition, the selection of pipe diameters takes into account many aspects, from the pipe material, the flow rate of the water flowing through the pipe, the number of elements that can cause loss, to the water meter or the use of special equipment.

Pipe diameters are usually expressed in nominal diameters (DN), which are defined by measurements such as outside diameter, inside diameter and wall thickness. For example, a pipe with a nominal diameter of 1/2 inch can be measured as 21.3 mm outside diameter, 15.7 mm inside diameter and 2.8 mm wall thickness.

These dimensions are standardized worldwide according to the technical drawing rules and are the same in Turkey, Africa and other countries.

Pipes used in electrical installations are usually manufactured in certain standard lengths and outer diameters. These pipes may be designed as threadless and manufactured from high quality steel for ease of installation. In heating installations, the most suitable pipe diameter is selected by taking into account the average pressure drops in order for the pipe network and operating costs to be economical.

Calculation of Pipe Diameters

Calculation of pipe diameters plays a critical role in the design of plumbing systems and this process varies according to the type of fluid, the requirements of the system and the operating conditions. Pipe diameter calculation is usually done using specific formulas and calculation methods. These methods are

- flow rate of the fluid,

- pressure loss

- speed and

- viscosity

takes into account parameters such as.

In the pipe diameter calculation process, the fluid flow rate required by the system is first determined. This flow rate refers to the amount of fluid that the pipes in the system must carry and is usually expressed in units such as liters per second (L/s) or cubic meters per hour (m³/h).

Then, taking into account factors such as the properties of the fluid such as viscosity and density, the pipe material and the length of the pipeline, the most suitable pipe diameter is selected according to the desired pressure drop of the system.

Some common formulas used in pipe diameter calculations are as follows:

- Darcy-Weisbach equation: This equation is used to calculate friction losses in the pipeline and includes factors such as pipe diameter, velocity of the fluid, length of the pipeline and viscosity of the fluid.

- Hazen-Williams formula: Used especially for pipelines carrying water, this formula takes into account factors such as the diameter of the pipe as well as the velocity of the fluid and the roughness of the pipe material.

- Manning formula: Used for open channels and gravity flow systems, this formula takes into account factors such as pipe diameter, slope and surface roughness of the fluid.

These formulas used in pipe diameter calculations are usually applied automatically by engineering software and calculation tools. These software simplify complex calculations, helping engineers achieve fast and accurate results.

Other important factors to consider in pipe diameter calculations include the configuration of the pipeline, current and future flow conditions, safety requirements of the system and cost effectiveness. Compliance with international standards and local regulations also plays an important role in the calculation process.

As a result, accurate calculation of pipe diameters is vital to ensure efficient and safe operation of plumbing systems. Therefore, pipe diameter calculations are one of the most basic and most important aspects of plumbing engineering.

As a result, the choice of installation pipe diameters has a direct impact on the functionality and economy of the installation. Selecting the right pipe diameters is crucial for energy efficiency, cost savings and system safety.

Resources that provide detailed information and calculation methods for installation engineers and practitioners are indispensable for successful installation system design and implementation.

Click here to order submersible pump pipe. Click here to get information about submersible pumps.